A long-term effort to secure industry’s access to critical spare parts and components is now underway. The aim is to contribute to a competitive industry by reducing the risk of supply chain disruptions.

The basic industry is an important cornerstone of Sweden’s economy and is completely dependent on spare parts to function. Supply chains are often global, which has proven to be vulnerable when international events affect trade. The newly launched initiative aims to help companies become more resilient to external disturbances while creating new business for local suppliers.

“We see an increasing need to adapt the manufacturing industry in response to transition needs and negative changes in the world around us. At the same time, we will maintain and ensure continuity and competitiveness in the Swedish process industry,” says Nicklas Tarantino, who is responsible for the Sustainable Steel Region investment.

A test arena in a real environment

Based on Dalarna, Gävleborg and Värmland, cooperation to strengthen the industry’s competitiveness is already underway. Cooperation is now being taken to the next level through a new long-term initiative, which will be scaled up nationally and internationally.

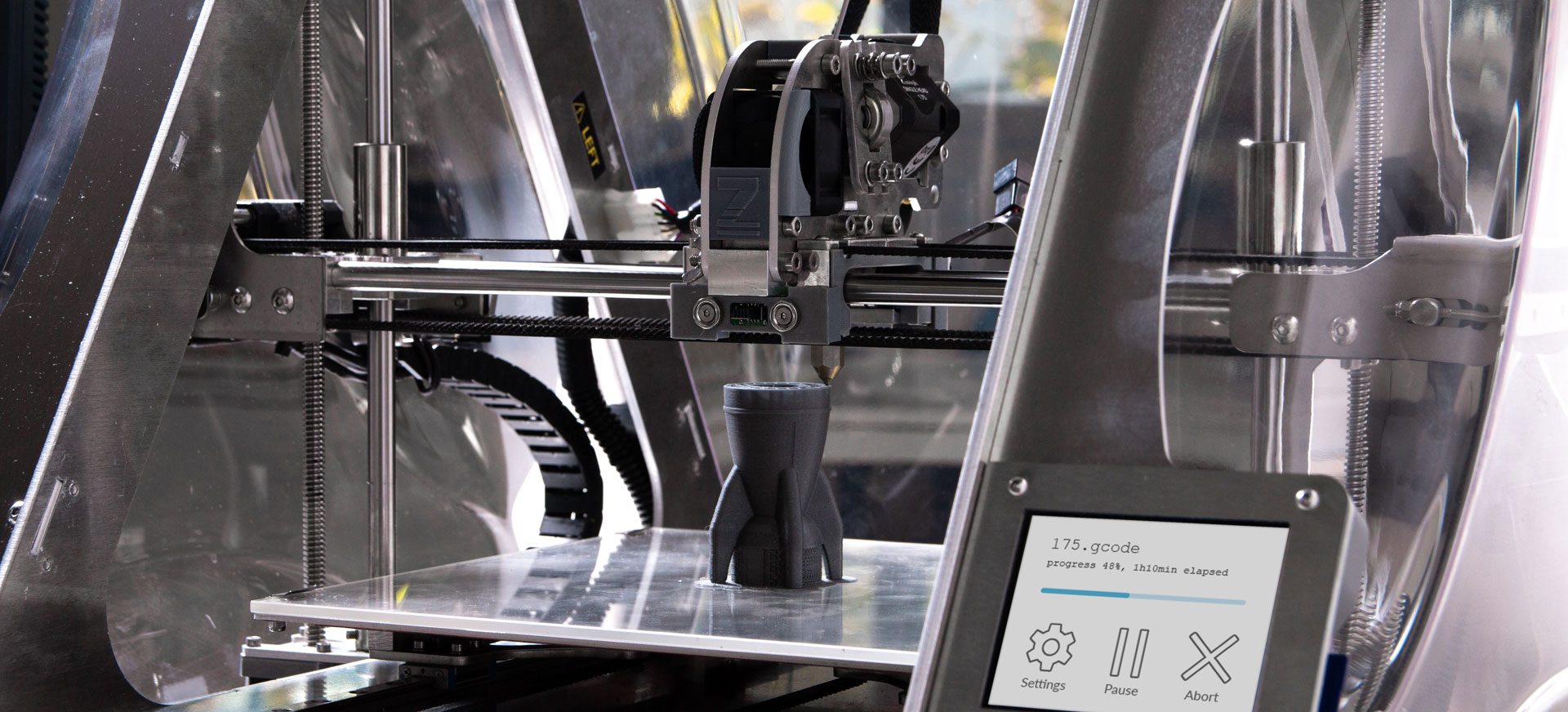

The initial work is based on creating a test arena where local companies and supply chains can develop in a real environment, a so-called system demonstrator. The goal is to be able to produce spare parts on demand, i.e. based on the customers’ needs and delivered locally, quickly and with considerably less climate impact than today. Among other things, the initiative will explore more reliable solutions with 3D printing, where digital files are sent instead of physical components.

“We will now step up by gathering more parts of the value chains to jointly develop and influence the system,” says Nicklas Tarantino.

Nicklas Tarantino, Sustainable Steel Region.

Increased commerce and new job opportunities

The new infrastructure is expected to provide more local business and jobs, as well as reduce costs and the risk of disruptions. The work is based on a preliminary study conducted by stakeholders from the engineering industry, the process industry, academia and innovation systems.

Participants will build a market and capacity for on-demand manufacturing, while developing and influencing technology, business models, infrastructure, policy and culture. The work has a long-term vision of ten years, but will be started as a four-year project in which Vinnova, Region Värmland, Region Dalarna, Region Gävleborg and industry will jointly contribute a total of SEK 50 million.

“If we are to be able to meet the industry’s need for safe and fast spare parts and components, we need to jointly develop supplier systems and new manufacturing methods in the workshop industry. Prerequisites such as technology and competence already exist, but a structured system is needed to establish on-demand production on a larger scale,” says Stefan Jansson at Sustainable Steel Region, who leads the operational work.

Background info

Both the EU and the Swedish government are investing resources in securing European industry, which will be done with alternative value chains and increased domestic production. A preliminary study conducted in North-Middle Sweden demonstrates the possibility of developing resilient production and robust supply chains with demand-oriented and additive manufacturing. The insights from the study form the basis for this initiative, which will start in 2024 January.

Read more about the preliminary study here (swedish).

The new project is called “On demand – local and sustainable production of critical spare parts and components 2033”. Participating parties include Alderholmens Mekaniska AB, Complete Solution Seffle AB, Enerco Mechpart AB, Holmen Iggesund Paperboard AB, SSAB EMEA AB, Ivaldi, Lasertech LSH AB, Triton Valsteknik AB, Västerdalarnas Mekaniska Industri AB, RISE, Propell, Sandbacka Science park, Paper Province, Karlstad University, Dalarna University College, Gävle University College, Region Dalarna. The project is led by Sustainable Steel Region and financed by Vinnova, Region Dalarna, Region Värmland and Region Gävleborg.